According to Coffee with an Architect blog, the answer is "21".

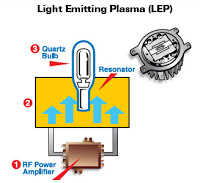

Louis Poulsen “artichoke” luminaire.

One to sketch out the concept;

One to model it in Revit;

One to question the concept… “Does it have to screw?”;

One to write an addendum informing the contractors;

One to find the spec section and ASTM standards for screwability;

One to fill out the LEED paperwork for said lightbulb;

One to suggest a “stainless steel” lightbulb;

One to suggest a skylight instead of the lightbulb;

One to research alternate methods of screwing on the internet (Don’t google that while in the office);

One to suggest having a charette to brainstorm ideas about screwing in lightbulbs;

One (intern) to build a chipboard model of the lghtbulb;

One to suggest recessing the lightbulb;

One to issue addendum # 35 to have the contractor reverse the swing on the door in the room so the light switch for the lightbulb can be relocated to the other wall;

One to ask the design principal in charge to call the client to let them know we’re screwed;

One to call the structural engineer to see if the beam running through the lightbulb can be moved;

One to render the space showing a Louis Poulsen “artichoke” lamp instead of the lightbulb;

One to ask: “what the lightbulb wants to be?”;

One to discuss Le Corbusier’s use of lightbulbs throughout Villa Savoye;

One to google “Snohetta / lightbulbs”;

One to remove the boundary between the interior and the exterior of the lightbulb;

And finally;

One turn off the light while muttering “less is more…”

Louis Poulsen “artichoke” luminaire.

------------

The answer above was written by an architect. Otherwise, the answer might have been:

------------"None". The architect depends on a contractor to realize the design intent.

The site also sells tee shirts. Here is my favorite: