At the end of each year, the staff at Chusid Associates nominates and votes on its list of the Ten Best New Building Products of the year. Our intention was to blog about all ten, but we got busy and only managed to write about a few of the winners. Without delaying the project further, here is our truncated list:

The pace of innovation continues. The tough economic times are actually proving a boon to some companies, as they use the opportunity for research and launching new products that, in the continual press of sales during a good year, would normally get buried. Several of this year's entries are innovations on ages-old problems, while others represent the intersection of several cutting-edge technological developments. A few were included not because the actual products were significant, but because of the trends they represent.

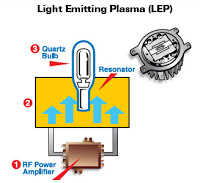

1. Plasma Lighting: Solid state lighting, in the form of LEDs, have been a major trend for the past few years. Now plasma lighting is taking the spotlight, offering in some cases twice the lumens per Watt of LEDs. Right now most of the plasma lighting available is for stadium and street lamp-sized installations, but miniaturization to commercial and industrial scale seems inevitable.

Multiquip's H2LT Hydrogen Fueled Light Tower drew a lot of attention at World of Concrete for combining low-energy, high-intensity light with quiet, low-polluting hydrogen fuel cells. The plasma light bulb produces 22,000 lumens while consuming only 255 watts, with a life expectancy of up to 50,000 hours. Beyond its energy efficiency, the tower made our list for one simple reason: it is sparking imaginations. At the show, people were walking away from the Multiquip booth discussing new ways and places they could use this technology, sewing the seeds for the next generation of innovations.

2. Phase-Change Insulated Glass: Another ripe field for innovations is combining multiple successful technologies into a single high-performing system. This becomes especially important in sustainable design when building systems often need a higher level of flexibly to meet multiple design objectives simultaneously; natural daylighting is advantageous, for example, but too much interferes with the building's thermal performance and energy use.

Glass-X, from Greenlight Glass, addresses exactly this problem. The core of the system is phase-changing glass that stores or releases thermal energy in the process of converting from solid to liquid states. Glass-X controls thermal transfer, essentially creating virtual thermal mass to help warm or cool the interior as needed. A prism system takes advantage of seasonal changes in the sun's position to reflect hot summer light, while allowing more light, and heat, transfer in winter months.

Glass is one of our favorite building materials around the office; the amount of versatility and innovation in glass construction is staggering, and the trend looks set to continue for the next few decades. The next winner is another glass product.

Ornalux glass has special ultraviolet patterns that are visible to birds, but not detectable by the human eye. This means birds see the window and identify it as an obstacle, and humans get to enjoy natural lighting and an unobstructed view.

Click here for our 2009 list. And stay tuned for our best of 2011 list.

The pace of innovation continues. The tough economic times are actually proving a boon to some companies, as they use the opportunity for research and launching new products that, in the continual press of sales during a good year, would normally get buried. Several of this year's entries are innovations on ages-old problems, while others represent the intersection of several cutting-edge technological developments. A few were included not because the actual products were significant, but because of the trends they represent.

1. Plasma Lighting: Solid state lighting, in the form of LEDs, have been a major trend for the past few years. Now plasma lighting is taking the spotlight, offering in some cases twice the lumens per Watt of LEDs. Right now most of the plasma lighting available is for stadium and street lamp-sized installations, but miniaturization to commercial and industrial scale seems inevitable.

Multiquip's H2LT Hydrogen Fueled Light Tower drew a lot of attention at World of Concrete for combining low-energy, high-intensity light with quiet, low-polluting hydrogen fuel cells. The plasma light bulb produces 22,000 lumens while consuming only 255 watts, with a life expectancy of up to 50,000 hours. Beyond its energy efficiency, the tower made our list for one simple reason: it is sparking imaginations. At the show, people were walking away from the Multiquip booth discussing new ways and places they could use this technology, sewing the seeds for the next generation of innovations.

|

| This all-glass wall is energy efficient. |

Glass-X, from Greenlight Glass, addresses exactly this problem. The core of the system is phase-changing glass that stores or releases thermal energy in the process of converting from solid to liquid states. Glass-X controls thermal transfer, essentially creating virtual thermal mass to help warm or cool the interior as needed. A prism system takes advantage of seasonal changes in the sun's position to reflect hot summer light, while allowing more light, and heat, transfer in winter months.

Glass is one of our favorite building materials around the office; the amount of versatility and innovation in glass construction is staggering, and the trend looks set to continue for the next few decades. The next winner is another glass product.

3. Bird-Visible Glass: When I was five I once ran full-speed into a closed glass door, face first, so I have a lot of sympathy for birds flying into windows. The problem is so prevalent that it has become embedded in our culture; birds hitting windows is an instantly recognizable slapstick troupe. But the real-world side is not funny; estimates are that almost 1 billion birds are killed by window collisions in the US each year.

Click here for our 2009 list. And stay tuned for our best of 2011 list.

This product points at an important change that’s rippling through the construction industry. The industry is notoriously slow to change, partly because our established business and legal practices make change discouragingly risky. This reluctance promotes a tendency to live with problems instead of solving them. Then along comes an independent thinker who knows the way things are always done but has the courage to say, “Just because we’ve done it this way for 20 years doesn’t make it the best way.” Construction people are looking at their allegiance to the tried-and-true and wondering if convention itself has become a risk, the risk of becoming irrelevant, impractical, and unsustainable.

This product points at an important change that’s rippling through the construction industry. The industry is notoriously slow to change, partly because our established business and legal practices make change discouragingly risky. This reluctance promotes a tendency to live with problems instead of solving them. Then along comes an independent thinker who knows the way things are always done but has the courage to say, “Just because we’ve done it this way for 20 years doesn’t make it the best way.” Construction people are looking at their allegiance to the tried-and-true and wondering if convention itself has become a risk, the risk of becoming irrelevant, impractical, and unsustainable.