Too frequently, poorly written specifications make it difficult to bid construction projects. I saw another example of this today in a specification section for a large project designed by a major architectural firm. Here are some of the errors in the document:

1. It specified a product that has not been manufactured in more than five years.

2. While the product was identified by its manufacturer, the manufacturer was not among those named in the paragraph listing acceptable manufacturers.

3. Accessories necessary for the installation of the product were specified to be by another manufacturer with incompatible accessories.

4. The product was specified to be made with "FSC wood". While I assume "FSC" is an abbreviation for "Forest Stewardship Council", a wood rating agency, this was not stated by the specification, creating ambiguity.

5. Moreover, FSC has several standards for wood. Yet the required grade was not specified. While I assume the architect wants FSC-Certified wood to comply with LEED requirements, the vague spec could allow other firms to supply FSC-Controlled or FSC-Mixed woods that are less costly and contribute less value to LEED compliance.

6. While the section specifies submittal of data substantiating recycled content in compliance with LEED requirements, it does not require submittal of data substantiating the LEED value of the wood. This casts doubt on my assumption that the intent of the document is to require FSC-Certified wood.

These errors were found while skimming the specification; perhaps closer scrutiny would reveal further obfuscations.

If you have to bid a specification like this, the proper response -- at least according to typical instructions to bidders -- is to request a clarification from the architect. As a material supplier, the instructions to bidders probably require you to submit your question through a prospective subcontractor who would, in turn, submit the question to a prospective general contractor to forward to the design firm. By the time the architect or engineer issues an addendum answering the inquiry, there may be little time left to prepare your bid.

The sloppiness in the specification is to the disadvantage of a responsible supplier that tries to ferret out the designer's intent and bid accordingly. Other contractors will exploit the vagueness of the spec to submit the lowest quality work they can get away with.

WHAT TO DO

As an Architect, Certified Construction Specifier, and Fellow of the

Construction Specifications institute, I am embarrassed by the

prevalence of such substandard work by members of my profession.

In outrage, I imagine a website to which bidders could anonymously submit defective specs. Each week, a panel of reviewers would select one example as the "Defectification of the Week," posting the section and the name of the culpable design firm and notifying to the firm's client. Perhaps fear of such public shaming would motivate designers to give more attention to the quality of their construction documents.

Yet the better response is to expend my energy training and encouraging specifiers to raise the standard of care in the industry.

Here are some ways manufacturers can play a role in this campaign:

1. Train your team so they understand the principles of specifications. A great way to do this is by encouraging your sales reps, estimators, engineers, and customer service staff to study for and pass CSI's Construction Document Technologist (CDT) exam.

2. Publish well written guide specifications that architects and engineers can use as the basis for preparing project specifications. And,

3. Assist specifiers to prepare clear, complete, and concise project specifications by providing technical and sales support. If you develop a reputation of being a fair broker that knows your product category, many specifiers will let you review and provide feedback about their specs prior to putting them out to bid.

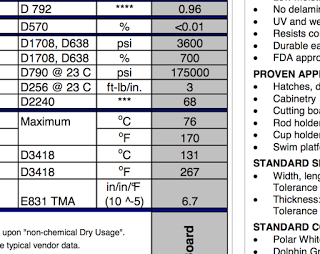

Please put a date or version number on your sales literature,

especially technical information. It will make it easier for your

customers to use the most current literature, simplify communication

between us, and help avoid conflicts due to reliance on out-of-date

information.

Please put a date or version number on your sales literature,

especially technical information. It will make it easier for your

customers to use the most current literature, simplify communication

between us, and help avoid conflicts due to reliance on out-of-date

information.