New tools often lead to new building materials that can optimize the benefits of the new technology. How will you be able to benefit from the emerging tool technology of hand held robots? Here is a report on recent research:

Researchers develop intelligent handheld robots

What if handheld tools know what needs to be done and were even able to guide and help inexperienced users to complete jobs that require skill? Researchers at the Univ. of Bristol have developed and started studying a novel concept in robotics—intelligent handheld robots.

Historically, handheld tools have been blunt, unintelligent instruments that are unaware of the context they operate in, are fully directed by the user, and critically, lack any understanding about the task they are performing.

Dr. Walterio Mayol-Cuevas and PhD student, Austin Gregg-Smith, from the Dept. of Computer Science, have been working in the design of robot prototypes as well as in understanding how best to interact with a tool that “knows and acts”. In particular, they have been involved with comparing tools with increasing levels of autonomy.

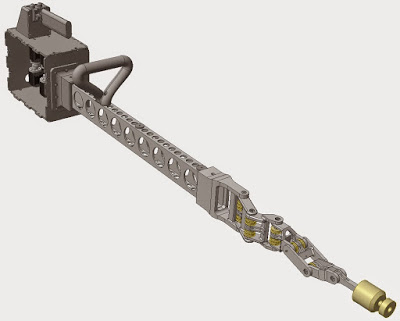

Compared to other tools such as power tools that have a motor and perhaps some basic sensors, the handheld robots developed at Bristol are designed to have more degrees of motion to allow greater independence from the motions of the user, and importantly, are aware of the steps being carried out. This allows for a new level of co-operation between user and tool, such as the user providing tactical motions or directions and the tool performing the detailed task.

Handheld robots, aim to share physical proximity with users but are neither fully independent as is a humanoid robot nor are part of the user’s body, as are exoskeletons. The aim with handheld robots is to capitalize on exploiting the intuitiveness of using traditional handheld tools while adding embedded intelligence and action to allow for new capabilities.

Dr. Mayol-Cuevas, Reader in Robotics Computer Vision and Mobile Systems, said: “There are three basic levels of autonomy we are considering: no autonomy, semi-autonomous when the robot advises the user but does not act, and fully autonomous when the robot advises and acts even by correcting or refusing to perform incorrect user actions.”

The Bristol team has been studying user’s task performance and user preferences on two generic tasks: pick and drop of different objects to form tile patterns, and aiming in 3-D for simulated painting.

Austin Gregg-Smith, a PhD student who is sponsored by the James Dyson Foundation, added: “Our results indicate that users tend to prefer a tool that is fully autonomous and there is evidence of a significant impact on completion time and reduced perceived workload for autonomous handheld. However, users sometimes also expressed how different it is to work with this type of novel robot.”

|

| The plans for constructing the robot on a 3D printer can be downloaded. |

I am quite sure, however, that there will also be a need for manual hammer, screw driver, knife, shovel, trowel, and pliers, and also the trained mechanics that know how to use them. At least, I hope there will be; otherwise we can all pack up and collect unemployment.

Source: Univ. of Bristol via rdmag.com, 05/27/2015

More info: http://handheldrobotics.org/