This is an encore of an article Michael Chusid wrote twenty years ago. Looking back, it is encouraging to see that many of the advances predicted then have now become part of every day design and construction practice. Yet fundamental challenges about improving communication and project quality still remain.

For many architects, integration of computer-based systems still means figuring out which end of the cable plugs into their personal computer. But the topic was given much greater meaning at the First International Symposium on Building Systems Automation-Integration held in June at the University of Wisconsin-Madison. This week-long conference, initiated by Varkie Thomas of the Chicago office of Skidmore Owings B Merrill, was devoted to "the integration of computer-based systems for planning, design, construction, and operation of buildings." The conference offered bold predictions for computer technology and its effect on architecture.

While an increasing number of architectural and construction tasks employ computers, the Symposium identified two major barriers preventing computer-aided design from achieving even greater productivity. First, computers have been applied essentially as "electronic pencils," speeding up manual processes but not changing the nature of the tasks. For example, specification are written as though word processors are just fancy typewriters and CAD drawings replicate the types of lines and abstractions used in traditional drafting. Second, computerized information is still transferred from one application to another by manual methods, leading to increased costs and errors in data processing. For example, it is rare for an architect's CAD file to be passed along for a contractor to use in construction engineering, and electronic product data are not passed along to owners for use in automated facility management. To overcome these barriers, conference participants presented an amazing variety of new computer-based systems and concepts that are already available or under development in laboratories around the world. They also called for new paradigms, based on integration of information and the building team, for the organizational structure of the building industries.

Computers and Practice

Many designers still practice what Tor Syzertsen from the Norwegian Institute of Technology called "Pencil and Paper-Aided Design (PPAD)." But he predicted that computers will soon be such an intrinsic part of architecture that we will drop the phrase "Computer-Aided" from our description of design. He called for the creation of "knowbots" to automate routine architectural tasks, many examples of which were presented during the week-long conference.

The Intelligent Design Checker, for example, can review a set of drawings for compliance with bullding codes and other standards. Nayel Shafei from Prime Computers, Inc., described how the New York State Facilities Development Corporation uses the program to check compliance of hospital designs with National Fire Protection Association standards and the New York State Life Safety Code. The Checker flagged so many violations in drawings submitted for final approval that the Facilities Development Corporation now requires architects to run the program during the design phase of projects, when corrections can be more easily made.

Architects typically design a building envelope and then pass it to mechanical engineers for an energy-use evaluation. This results in slow and costly iteration of design between architects and engineers. To improve this situation, both Larry Degelman of Texas A&M University and Edna Shaviv of the Israel Institute of Technology presented expert systems that integrate energy analysis and architectural design. Their systems allow architects to visualize buildings in 3D and simultaneously receive feedback on the energy consequences of design decisions. Both are using knowledge-based programs to suggest U-values, window placement, and design strategies to satisfy energy-code constraints.

Mehdi Khalvati from ASG explained that CAD programs could become "integrated architectural systems." ASG software, which runs with AutoCAD, links graphic information to specification writing, cost estimating, and product information. In a software package that ASG distributes for Boise Cascade, wood beams are treated as objects that contain information about their performance characteristics and limitations rather than just as lines; the program can automatically size and arrange wood floor framing members.

Expanding upon this theme, a team from Carnegie Mellon University demonstrated ARMILLA, which incorporates expert systems with a CAD drawing tool to aid the design of a building's structural, HVAC, plumbing, and other systems. A knowledge-base of engineering rules automatically makes trade-offs to coordinate the placement of beams, ducts, and risers.

New Models for Architects

Traditional architectural drawings, even those produced with the latest 3D CAD programs, are abstract geometrical representations of building components; the meaning of the lines is determined by the architect.

Computerized models, on the other hand, are constructed of "object-oriented" representations of each building space and component. "Object-oriented" is the computer equivalent of the architectural concern for the nature of materials; it is Louis Kahn's asking a material what it "wants to be." Object-oriented databases key building elements to information about what they are, their performance, and their relationships with other objects. Objects interact with each other according to knowledge-based rules and constraints. "Self-knowledge" enables objects to assert themselves to automatically generate designs or construction and facility management reports. Instead of the static abstraction of traditional drawings, this kind of computer model portrays a virtual reality that responds to changes in materials and conditions as would real buildings.

Visualization Software that creates photographic-quality 3D pictures of buildings will be valuable for both client presentations and as construction planning tools. Simulations will enable designers and owners to predict operating loads more accurately and to optimize the structure's performance by adjusting for varying conditions, thus reducing the need to over compensate for safety factors. And as new user interfaces are refined, architects may find themselves working in cyberspace environments that convey the illusion of being able to manipulate computer-generated items in the actual space.

Other developments in computer science presented at the Symposium that may affect architectural practice include neural nets, hypertext, artificial intelligence, and multimedia. Anticipation of these tools led to heated discussion about where the ultimate boundaries between human and machine capabilities might be. Some argued that creativity and aesthetics were not feasible or appropriate uses of computers. Shaviv countered with the example of a student with no architectural training who developed a program to draw housing plans based on code restrictions and a set of rules defining spatial relationships. "Some of the schemes the computer made were of great originality and beauty, designs a trained architect would never have dreamed of." Others argued that computers could stimulate human creativity by freeing designers from routine chores and presenting a greater range of options for them to consider. One software developer believed human intuition will remain an essential part of architecture; his program includes a "help key" that provides information unrelated to the task at hand to stimulate the user to make problem-solving breakthroughs.

The Need for a Standard

Developing the standard code necessary for object-oriented models will be an enormous undertaking and may not be practical in a fragmented industry that supports a multitude of incompatible computer and software systems. To overcome this, the Symposium struggled with standards and technical guidelines for exchanging computer generated information directly between systems and across the building industry. Current exchange protocols like the Initial Graphics Exchange Specification (IGES) and AutoDesk's DXF format primarily exchange geometrical drawing data. New standards are required to accommodate the richer information environment of object-oriented models.

The leading proposed standard is the Standard for The Exchange of Product Model Data (STEP). STEP is being coordinated by the International Organization for Standardization (ISO) and by the Product Data Exchange (PDES) in the United States. A PDES brochure explains that STEP "will provide a complete, unambiguous, computer interpretable definition of the physical and functional characteristics of each unit of a product throughout its life cycle. (It) will enable communications among heterogeneous computer environments; integration of systems that support design, manufacturing and logistic function/processes; and support automatic, paperless updates of system documentation."

Development of a comprehensive data exchange standard will be extremely costly but is of paramount importance to automation and integration; but funding for the construction industry's effort is problematic. Participants in the Symposium, however, felt that development of STEP is of such importance to United States competitiveness in global construction that they called for a government effort comparable to the building of the Interstate Highway system. "Who will be the President Eisenhower to make it happen?" one participant asked.

Life-Cycle Models

The ability to share a common building model will change the organization of building projects. Duvvuru Sriram from MIT called current design methods over-the-wall engineering. "The architect works on a design and then throws it over the wall to an engineer. The project is thrown over the wall to a contractor who uses the drawings as a sketchpad to figure out how the building will really be built, and it is eventually thrown to the building owner who has to figure out how to operate the facility." He proposed a knowledge-based management system and distributed databases that would facilitate collaborative design among all building team members.

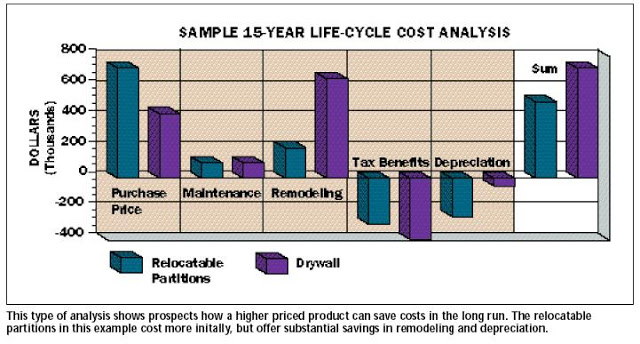

Information must also be managed so that it has value throughout the life-cycle of a building. As information is gathered, from the earliest planning stages through demolition, it should be sorted for value and stored in an accessible electronic form. Instead of merely automating current procedures, every part of architectural practice must be reassessed While putting product catalogs on to computer diskettes is a necessary first step, we should not lose sight of the need for an Electronic Data Interchange (EDI) system so that product data can flow directly from a manufacturer's catalog into a project database and then back into a manufacturer's production scheduling program without the time and expense of shop drawings. Owners will start demanding computer models for use in space planning, energy management, preventive maintenance, and operating systems; the quality of a building's database will be an asset they can carry to their bottom line.

The complexities of modern construction have created building teams with experts in many fields. Future architects may be able to work with fewer consultants as expert systems become more powerful and electric databases provide easier access to specialized information. This should lead to leaner and more productive building teams, but will require new approaches to architectural education and Practice. Ron Wooldridge of The Locke Group warned that "the good news is that 45 architects with computers will be able to do the work 50 people working manually. The bad news is that the 45 may not be a subset of the current 50." He urged architects to use integration and automation to add value to their work and to develop the knowledge-based systems and databases that would enable their firms to regain competitiveness.

The final advice from the Symposium is to not become too married to the current generation of AEC computers and applications. Rapid changes are coming that may make your personal computer as obsolete as a slide rule. Firms that accept the challenge of automation and integration will have to weather a turbulent period of industry and professional realignment, but are likely to emerge more competitive then before.

Have a question you'd like us to answer?

Send an email to

michaelchusid@chusid.com

By Michael Chusid, originally published in Progressive Architecture, ©1991