A recent article in Environmental Building News discusses the environmental credentials of Autoclaved Aerated Concrete and then asks, "Is there space for AAC in the U.S. market?"

Twenty-five years ago, I wrote an article for Progressive Architecture magazine in which I called AAC, "the best building product you can't buy." That is still true in most of the US. Despite numerous attempts and millions of dollars spent to build plants in several parts of US, there are only two producers in North America.

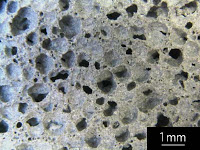

AAC is an ultra lightweight precast concrete product that is 80% air by volume. It has good structural, environmental, fire, and other performance characteristics. It has been used for 80 years in Europe, and is one of the most widely used building materials worldwide.

Chusid Associates has been a consultant to many companies that looked at AAC as an investment opportunity. Most of my clients decided not to invest. Those that did invest either bailed soon after, or went broke. From that experience, I offer the following reasons why AAC has had only limited success in North America:

1. While Europe was developing AAC, the US construction industry was developing metal buildings, light gage steel framing, concrete masonry units, and prestressed concrete. Those industries are now mature and a formidable competitive barrier to an innovative product with high start-up costs.

2. More recently, new technologies offer many of the benefits of AAC without the high capital costs of building and operating an AAC factory. Consider, for example, stay-in-place concrete forms, prefabricated light gage steel panels, and ultralight aggregates that can be used to make a cellular concrete that does not need autoclaving.

3. The high cost of an AAC factory creates a huge debt burden. While lighter than conventional concrete, AAC is still bulky and heavy, limiting the practical size of a distribution territory. These factors drove businesses into bankruptcy when demand didn't grow as quickly as expected or when the regional economy slumped.

4. Many of the European firms that invested in US factories did not understand the US market and made major strategic blunders. These blunders tainted the industry in the eyes of many investors and builders.

5. Even with increased appreciation for environmentally sound buildings, most construction in the US is still not very interested in green. Most home builders will continue to build with wood, for example, even though it burns and rots, because it is less costly.

In theory, AAC is such an attractive product that people get dazzled and become true believers. I call this, "Tobermorite Fever," named for the mineral that makes up AAC.

But let's look at it from another perspective. The construction industry in North America is fragmented into many regional markets. The failure rate for all innovative construction products is high. So the fact that there are viable producers in Florida and just across the Texas-Mexico border, plus designers, engineers, and installers that are well versed in the product, should be seen as a success for the AAC industry.

An online search on "Chusid" and the words Autoclaved Concrete will return links to several articles I have written on the topic.

Twenty-five years ago, I wrote an article for Progressive Architecture magazine in which I called AAC, "the best building product you can't buy." That is still true in most of the US. Despite numerous attempts and millions of dollars spent to build plants in several parts of US, there are only two producers in North America.

AAC is an ultra lightweight precast concrete product that is 80% air by volume. It has good structural, environmental, fire, and other performance characteristics. It has been used for 80 years in Europe, and is one of the most widely used building materials worldwide.

Chusid Associates has been a consultant to many companies that looked at AAC as an investment opportunity. Most of my clients decided not to invest. Those that did invest either bailed soon after, or went broke. From that experience, I offer the following reasons why AAC has had only limited success in North America:

1. While Europe was developing AAC, the US construction industry was developing metal buildings, light gage steel framing, concrete masonry units, and prestressed concrete. Those industries are now mature and a formidable competitive barrier to an innovative product with high start-up costs.

2. More recently, new technologies offer many of the benefits of AAC without the high capital costs of building and operating an AAC factory. Consider, for example, stay-in-place concrete forms, prefabricated light gage steel panels, and ultralight aggregates that can be used to make a cellular concrete that does not need autoclaving.

3. The high cost of an AAC factory creates a huge debt burden. While lighter than conventional concrete, AAC is still bulky and heavy, limiting the practical size of a distribution territory. These factors drove businesses into bankruptcy when demand didn't grow as quickly as expected or when the regional economy slumped.

4. Many of the European firms that invested in US factories did not understand the US market and made major strategic blunders. These blunders tainted the industry in the eyes of many investors and builders.

5. Even with increased appreciation for environmentally sound buildings, most construction in the US is still not very interested in green. Most home builders will continue to build with wood, for example, even though it burns and rots, because it is less costly.

In theory, AAC is such an attractive product that people get dazzled and become true believers. I call this, "Tobermorite Fever," named for the mineral that makes up AAC.

But let's look at it from another perspective. The construction industry in North America is fragmented into many regional markets. The failure rate for all innovative construction products is high. So the fact that there are viable producers in Florida and just across the Texas-Mexico border, plus designers, engineers, and installers that are well versed in the product, should be seen as a success for the AAC industry.

An online search on "Chusid" and the words Autoclaved Concrete will return links to several articles I have written on the topic.