This is an encore of an article Michael Chusid wrote over 20 years ago. Since then, several AAC producers have attempted business in the US, and most have failed. While it is still an outstanding building material, I suspect that newer building systems on the market make it less likely that AAC will become a major product in the US. But I would love to be proven wrong.

Autoclaved Cellular Concrete (ACC) [now known as Autoclaved Aerated Concrete (AAC)] is a precast concrete foam that can be used for building blocks and panels. ACC is not produced or readily available in the United States or Canada but is a major building material throughout most of the world. As North American architects and builders increasingly compete in a global market, the domestic construction industry must consider building materials such as ACC to meet the construction needs of this country.

Indeed, increased attention in the United States is already being focused on ACC: Planning is under way for ACC factories in Florida and New Jersey. Several other entrepreneurs and foreign companies are actively investigating U.S. manufacturing or importation of ACC. A major materials company was close to a commitment to build several ACC production facilities in the U.S. until it redirected its plans last fall. West Virginia University, which has formed an ACC Study Center to act as a clearing-house for information, attracted over 50 interested parties to a national conference on ACC last November. And several demonstration projects have recently been constructed in the U.S. Further laying the groundwork for ACC here has been the evaluation of the material by the Council of American Building Officials and HUD. Other building code approvals are pending.

Manufacture and Properties

To produce ACC, a slurry of Portland cement, lime, silica sand or fly ash, and water is mixed with a small amount of powdered aluminum and poured into molds. The aluminum reacts chemically to release millions of tiny hydrogen bubbles that expand the concrete to as much as five times its original volume. Within a few hours, the concrete foam cures enough to be stripped from its mold. It is then sliced into blocks or slabs of the required size and steam cured in an autoclave. Because it is fully hydrated, ACC is more dimensionally stable than conventional concrete. In fact, ACC turns to rock, forming microscopic crystals of the mineral tobormorite, a form of calcium silicate hydrate.

What makes ACC attractive as a building material is its unique combination or properties. 11 is light weight, thermally efficient, fire resistant, durable, and load beating. ACC is typically produced at densities as low as 35-pounds-per- cubic-foot, less than that of wood. Its myriad small cells result in a thermal conductivity of about 0.8 Btu/ft2(hr)F/in thickness, significantly lower than conventional concrete or masonry; in mild climates, ACC walls or roof decks may require no additional insulation. ACC also is noncombustible; partitions only three inches thick can provide an amazing three hours of fire resistance.

ACC is relatively inexpensive to manufacture and erect, with installed costs estimated to be lower than most comparable building systems. ACCs light weight not only reduces structural dead loads, it can also boost productivity because larger blocks or panels can be lifted and placed without heavy equipment. Although large ACC blocks are fabricated with handles for easy lifting and fast erection, blocks can be used in the same !trays as conventional concrete masonry and laid with either thin mortar beds or surface bonded construction techniques. For panels, steel reinforcing is placed in the molds. Panels are factory cut to length and capable of any special edge or surface treatments. They can be used for exterior single wythe walls and cavity walls, fire rated partitions and shaft walls, and roof decks. Compared to other types of walls which m u a h assembled from any components, prefabricated ACC panels offer structure, insulation, fire protection, and weather resistance all in one piece. ACC also can be easily cut to fit field conditions using conventional hand or power tools. Wiring can be run in ACC without conduit by drilling or routing raceways in the material.

Design opportunities abound with ACC

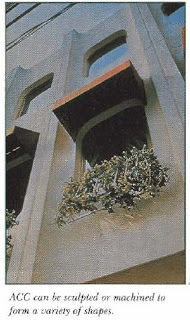

While the material can be exposed to weather, it readily accepts a variety of finishes including paint, stucco, synthetic plaster, ceramic tile, and thin brick or stone veneer. Because it can be cut so easily, the material also can be sculpted to form bas relief, ornament, graphics, and other architectural embellishments. Sculpting can be done either in the factory. Japanese firms, for example, produce ACC panels with a wide range of geometric surface patterns. And the ease with which custom designs can be executed will undoubtedly improve as the designers' CAD system is linked directly to the manufacturers' numerically controlled computer-aided manufacturing system.

ACC shares its ability to be shaped with the plastic foam used in exterior insulation and finish systems (EIFS). However, more elaborate shapes are possible with ACC because it does not need to be wrapped in fabric mesh. ACC is also similar to EIFS in that both are light weight, insulating, and economical. But ACC does not present the fire hazard of plastic foam, has fewer separate components to assemble, and is more durable. ACC is a "structural insulation and finish system."

The Material's Market

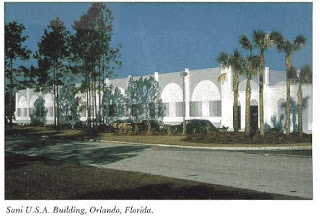

ACC was produced as early as the 1920s, but it was after World War II that its use rapidly increased. Commercialized first in Sweden and Germany, it spreads to the rest of Europe and then around the world. Today, over 200 plants in at least 35 countries produced more than eight billion cubic feet per year. The only North American Plant is in Mexico City, although a plant operated in Montreal during the 1970s and produced several hundred buildings. Buildings built with material from the Mexico City and Montreal plants have held up well and provided evidence of ACC'S performance in varied North American climates. Several ACC projects have been constructed recently in this country using imported materials. These include two projects in Florida: an office and factory for a Swedish firm and a housing prototype for a German developer. Another recent project for Consolidation Coal Company used ACC blocks in an underground mine to partition tunnels to create ventilation shafts. A primary advantage of ACC in the mine was that the blocks could be moved into place easily and with minimal risk of back injury.

But if ACC is such an outstanding building material why isn't it already widely used in the United States? This question has been asked for so many decades that it has fostered an atmosphere of skepticism which may be ACC's single biggest hurdle to overcome here. The answer sheds light on the marketing and economic forced that shape the palette of materials available to contemporary architects. Complete with autoclaves and the automated equipment to slice the loaf of green concrete into blocks and panels, an ACC factory costs an estimated $10,000,000. Because ACC is bulky to transport, each plant has only a limited market area from which to recover the initial investment. In this country, ACC not only faces an unknown market demand, but solidly entrenched competition from concrete masonry, metal building panels and roof decks, precast concrete, EIFS, gypsum board partitions, and other materials. The missionary work required to gain acceptance for a significantly different building material can take years these factors exceed the risks most investors are willing to take.

Coming changes in society and construction, however, appear to favor ACC's unique characteristics. For example, the construction industry is facing a growing shortage of skilled labor, which could favor prefabricated and easy-to-install ACC panels over field-fabricated masonry. Throughout most of our young country's history, wood has been to separate buildings with open space. As our country matures, however, the greater permanence and fire resistance of ACC may be in greater demand. And the growing desire to compete around the world, plus the cross-fertilization between U.S. designers practicing abroad and foreign developers working in the U.S., will undoubtedly continue to stimulate interest in ACC.

Another reason why ACC is attracting more attention is that it is an environmentally friendly material. ACC is inert and non-toxic. It is produced with environmentally sound, low cost, and readily available raw materials. In fact, by using fly ash, a waste product of coal-fired electrical generators, ACC even mitigates a solid waste disposal problem faced by electrical utilities. Manufacturing requires relatively small amounts of energy and does not release pollutants; scrap can even be ground and put back into the mix. Since it does not burn, ACC does not release toxic particles of combustion nor does it contribute to indoor air pollution problems. On the contrary, ACC allows vapors and concentrations of other gasses to diffuse through its cellular structure and has been endorsed by European environmental agencies, including the Federal Association for Healthy Building Products and the International Institute for Healthy Construction. Environmental concerns about plastic foam and fibrous insulation materials are other reasons to consider ACC as an alternative to currently used materials.

As with any unfamiliar building technology, designers and builders will have to learn how to specify and erect ACC. And while ACC is a proven building system, it may have to be modified to accommodate domestic construction practices. For example, windows and wall penetrations must be carefully detailed to avoid the entry of water into the cellular concrete. But other foreign building technologies, such as single-ply roofing and EIFS, have been integrated successfully into domestic construction practice: ACC will eventually find a place here, too. Architects with projects overseas should use the opportunity to gain experience with ACC. It is a building material t. hat you will be hearing more about and should prove to be a welcome addition to the architectural palette.

Have a question you'd like us to answer?

Send an email to michaelchusid@chusid.com

By Michael Chusid

Originally published in Progressive Architecture, Copyright © 1990

Autoclaved Cellular Concrete (ACC) [now known as Autoclaved Aerated Concrete (AAC)] is a precast concrete foam that can be used for building blocks and panels. ACC is not produced or readily available in the United States or Canada but is a major building material throughout most of the world. As North American architects and builders increasingly compete in a global market, the domestic construction industry must consider building materials such as ACC to meet the construction needs of this country.

Indeed, increased attention in the United States is already being focused on ACC: Planning is under way for ACC factories in Florida and New Jersey. Several other entrepreneurs and foreign companies are actively investigating U.S. manufacturing or importation of ACC. A major materials company was close to a commitment to build several ACC production facilities in the U.S. until it redirected its plans last fall. West Virginia University, which has formed an ACC Study Center to act as a clearing-house for information, attracted over 50 interested parties to a national conference on ACC last November. And several demonstration projects have recently been constructed in the U.S. Further laying the groundwork for ACC here has been the evaluation of the material by the Council of American Building Officials and HUD. Other building code approvals are pending.

Manufacture and Properties

To produce ACC, a slurry of Portland cement, lime, silica sand or fly ash, and water is mixed with a small amount of powdered aluminum and poured into molds. The aluminum reacts chemically to release millions of tiny hydrogen bubbles that expand the concrete to as much as five times its original volume. Within a few hours, the concrete foam cures enough to be stripped from its mold. It is then sliced into blocks or slabs of the required size and steam cured in an autoclave. Because it is fully hydrated, ACC is more dimensionally stable than conventional concrete. In fact, ACC turns to rock, forming microscopic crystals of the mineral tobormorite, a form of calcium silicate hydrate.

What makes ACC attractive as a building material is its unique combination or properties. 11 is light weight, thermally efficient, fire resistant, durable, and load beating. ACC is typically produced at densities as low as 35-pounds-per- cubic-foot, less than that of wood. Its myriad small cells result in a thermal conductivity of about 0.8 Btu/ft2(hr)F/in thickness, significantly lower than conventional concrete or masonry; in mild climates, ACC walls or roof decks may require no additional insulation. ACC also is noncombustible; partitions only three inches thick can provide an amazing three hours of fire resistance.

ACC is relatively inexpensive to manufacture and erect, with installed costs estimated to be lower than most comparable building systems. ACCs light weight not only reduces structural dead loads, it can also boost productivity because larger blocks or panels can be lifted and placed without heavy equipment. Although large ACC blocks are fabricated with handles for easy lifting and fast erection, blocks can be used in the same !trays as conventional concrete masonry and laid with either thin mortar beds or surface bonded construction techniques. For panels, steel reinforcing is placed in the molds. Panels are factory cut to length and capable of any special edge or surface treatments. They can be used for exterior single wythe walls and cavity walls, fire rated partitions and shaft walls, and roof decks. Compared to other types of walls which m u a h assembled from any components, prefabricated ACC panels offer structure, insulation, fire protection, and weather resistance all in one piece. ACC also can be easily cut to fit field conditions using conventional hand or power tools. Wiring can be run in ACC without conduit by drilling or routing raceways in the material.

Design opportunities abound with ACC

While the material can be exposed to weather, it readily accepts a variety of finishes including paint, stucco, synthetic plaster, ceramic tile, and thin brick or stone veneer. Because it can be cut so easily, the material also can be sculpted to form bas relief, ornament, graphics, and other architectural embellishments. Sculpting can be done either in the factory. Japanese firms, for example, produce ACC panels with a wide range of geometric surface patterns. And the ease with which custom designs can be executed will undoubtedly improve as the designers' CAD system is linked directly to the manufacturers' numerically controlled computer-aided manufacturing system.

ACC shares its ability to be shaped with the plastic foam used in exterior insulation and finish systems (EIFS). However, more elaborate shapes are possible with ACC because it does not need to be wrapped in fabric mesh. ACC is also similar to EIFS in that both are light weight, insulating, and economical. But ACC does not present the fire hazard of plastic foam, has fewer separate components to assemble, and is more durable. ACC is a "structural insulation and finish system."

The Material's Market

ACC was produced as early as the 1920s, but it was after World War II that its use rapidly increased. Commercialized first in Sweden and Germany, it spreads to the rest of Europe and then around the world. Today, over 200 plants in at least 35 countries produced more than eight billion cubic feet per year. The only North American Plant is in Mexico City, although a plant operated in Montreal during the 1970s and produced several hundred buildings. Buildings built with material from the Mexico City and Montreal plants have held up well and provided evidence of ACC'S performance in varied North American climates. Several ACC projects have been constructed recently in this country using imported materials. These include two projects in Florida: an office and factory for a Swedish firm and a housing prototype for a German developer. Another recent project for Consolidation Coal Company used ACC blocks in an underground mine to partition tunnels to create ventilation shafts. A primary advantage of ACC in the mine was that the blocks could be moved into place easily and with minimal risk of back injury.

But if ACC is such an outstanding building material why isn't it already widely used in the United States? This question has been asked for so many decades that it has fostered an atmosphere of skepticism which may be ACC's single biggest hurdle to overcome here. The answer sheds light on the marketing and economic forced that shape the palette of materials available to contemporary architects. Complete with autoclaves and the automated equipment to slice the loaf of green concrete into blocks and panels, an ACC factory costs an estimated $10,000,000. Because ACC is bulky to transport, each plant has only a limited market area from which to recover the initial investment. In this country, ACC not only faces an unknown market demand, but solidly entrenched competition from concrete masonry, metal building panels and roof decks, precast concrete, EIFS, gypsum board partitions, and other materials. The missionary work required to gain acceptance for a significantly different building material can take years these factors exceed the risks most investors are willing to take.

Coming changes in society and construction, however, appear to favor ACC's unique characteristics. For example, the construction industry is facing a growing shortage of skilled labor, which could favor prefabricated and easy-to-install ACC panels over field-fabricated masonry. Throughout most of our young country's history, wood has been to separate buildings with open space. As our country matures, however, the greater permanence and fire resistance of ACC may be in greater demand. And the growing desire to compete around the world, plus the cross-fertilization between U.S. designers practicing abroad and foreign developers working in the U.S., will undoubtedly continue to stimulate interest in ACC.

Another reason why ACC is attracting more attention is that it is an environmentally friendly material. ACC is inert and non-toxic. It is produced with environmentally sound, low cost, and readily available raw materials. In fact, by using fly ash, a waste product of coal-fired electrical generators, ACC even mitigates a solid waste disposal problem faced by electrical utilities. Manufacturing requires relatively small amounts of energy and does not release pollutants; scrap can even be ground and put back into the mix. Since it does not burn, ACC does not release toxic particles of combustion nor does it contribute to indoor air pollution problems. On the contrary, ACC allows vapors and concentrations of other gasses to diffuse through its cellular structure and has been endorsed by European environmental agencies, including the Federal Association for Healthy Building Products and the International Institute for Healthy Construction. Environmental concerns about plastic foam and fibrous insulation materials are other reasons to consider ACC as an alternative to currently used materials.

As with any unfamiliar building technology, designers and builders will have to learn how to specify and erect ACC. And while ACC is a proven building system, it may have to be modified to accommodate domestic construction practices. For example, windows and wall penetrations must be carefully detailed to avoid the entry of water into the cellular concrete. But other foreign building technologies, such as single-ply roofing and EIFS, have been integrated successfully into domestic construction practice: ACC will eventually find a place here, too. Architects with projects overseas should use the opportunity to gain experience with ACC. It is a building material t. hat you will be hearing more about and should prove to be a welcome addition to the architectural palette.

Have a question you'd like us to answer?

Send an email to michaelchusid@chusid.com

By Michael Chusid

Originally published in Progressive Architecture, Copyright © 1990