The construction products industry has, for the past few years, been consumed by the struggle to either be green or appear green. It's caused me to reflect on the different marketing struggles faced by old products trying to green themselves vs. new ones that are built green from the bottom up.

The construction products industry has, for the past few years, been consumed by the struggle to either be green or appear green. It's caused me to reflect on the different marketing struggles faced by old products trying to green themselves vs. new ones that are built green from the bottom up.

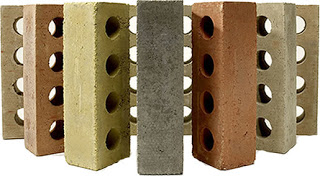

An example of a green-from-day-one marketing challenge is CalStar Products, Inc., a Northern California-based company founded to create more sustainable cementitious products. (www.calstarproducts.com) They are in the final development stages of a non-clay, non-fired brick. It is made dominantly of fly ash, a recycled smokestack byproduct.

This innovative product was developed to address the high energy consumption and concomitant CO2 emission associated with making fired clay brick (the most common form of brick). The process for firing clay into brick involves up to three days in a kiln at about 1000 degrees F. During most of the past 100 years, that's resulted in about 1.3 lbs of CO2 being sent up the smokestack and into our air for every common 4.1-lb. clay brick produced. Coal-fired kilns can cough up additional smokestack pollution problems if they're not properly scrubbed.

CalStar's fly ash brick isn't kilned, and the energy consumption of its prototypes is coming in at about 15%-20% of a fired clay brick. They hope to get it down to 10% when they have fully ramped up commercial production. They've done testing to demonstrate that their brick meet the same ASTM structural standards that clay brick have to meet. So their marketing story is about a product that can be substituted for clay brick while making a big reduction in CO2 related to global climate change.

CalStar's biggest challenge is, in fact, that their product is innovative. It hasn't been built with before. Not only must CalStar introduce its new solution to the marketplace, it must also overcome the industry-wide reluctance to be the first to try anything new, a type of caution for which design professionals and construction contractors are notorious. Construction-related liabilities can be enormous, so a decision-maker considering a really innovative product has to be wondering whether human progress is worth the risk of his personal livelihood. CalStar needs to simultaneously tell their sustainability story and overcome the well-entrenched fear of change.

CalStar is tackling this challenge with a combination of science and good public relations. They are testing and refining their product rigorously, both to meet industry-wide brick standards that will make it a equivalent and approvable substitute, and also to ascertain that the product is safe, responsibly made, and reliable. At the same time, they are working with construction PR professionals to educate the industry in depth about the issues, tell their story and build confidence in their product, and make the case for brick masonry that is more friendly to the planet.

The clay brick industry (www.gobrick.com) has the opposite marketing challenge. They are the dominant player, and their product is a very well established, economical, reliable building material. But the sustainability profile of brick is becoming more and more of an issue for them.

The clay brick industry's challenges are a) fighting a rearguard action against competitive masonry products like concrete brick and new green bricks such as CalStar's, and b) making their own product either be greener or appear greener.

On the greening front, the clay brick industry has made a mighty effort to reduce their energy consumption and pollution. They claim a per-brick-reduction in embodied energy of about 1/3. Unfortunately, this still leaves a lot of CO2 between them and their nearest competition, concrete brick. Moreover, they may be reaching the lower limit of energy consumption possible within the nature of clay.

The clay brick industry has responded to this challenge with a deft public relations campaign. They have, first of all, tried to brand fire clay brick as the only true brick, excluding concrete, adobe, and others. They use language very effectively in this effort, referring to concrete bricks as cricks (see article on newhomesource.com, for example) or referring to competitive products in quotes, as in: fly ash "brick".

They are making the most of the green properties they do possess, such as durability, thermal mass effect, insulation value, etc. Based on these properties, they have gone on the offensive, claiming to be the greenest building material available.

Personally, I'm not sure I buy every one of their claims, and I wonder how much of it is really just greenwashing. (That question comes up lately in regard to many products.) But professionally, I have to admire their strategy and their execution. They are using marketing methods effectively to make the most of their situation and extend the life of their product.

For more on brick and sustainability, please see our article from the May issue of The Construction Specifier.